Summary. In the realm of decorative commercial flooring, decorative epoxy flooring stands out as a vibrant and durable solution. Our offerings at PSC Flooring include the decorative epoxy resin quartz 4mm screed and the decorative epoxy resin flake system, both designed to transform commercial spaces. Take a cue from our successful project with Four Anjels Limited to see how these flooring options can revitalize your business environment.

There are two decorative commercial flooring options that PSC Flooring offer as part of their product portfolio: Decorative epoxy resin Quartz 4mm Screed and Decorative Epoxy Resin Flake System. Read on to find out more.

Decorative epoxy resin Quartz 4mm Screed

We blend clear epoxy resin with a decorative quartz aggregate to create decorative epoxy screeds. Quartz aggregate is available in a number of colours which when combined together formulate the desired colour pallet. The decorative epoxy resin quartz screed mixture is usually laid at a nominal 4mm thickness.

When dry the decorative epoxy resin quartz screed provides a high strength and chemically resistant flooring. Moreover, the decorative floor surface is ideal for use in commercial areas such as showrooms, reception areas etc.

Decorative Epoxy Resin Flake System

By adding decorative epoxy flakes to the newly laid wet resin, you achieve decorative epoxy resin flake flooring. You can create a random decorative effect by manually tossing the decorative flake mixture upwards. They float down to the wet binder coat broadcast.

In order to protect the finish, 2 coats of clear rein seal coat are applied to the surface. When dry the decorative epoxy resin flake system a fantastic way to enjoy a vibrant, colourful flooring surface for a number of commercial environments. For instance, reception areas, retails spaces, staff canteens, washrooms and changing areas.

Four Anjels – Decorative Flake System

PSC Flooring have recently completed installation of a Decorative flake resin system to 180 square metres for Four Anjels Limited. They are an award-winning bakery based in the heart of the Cotswolds.

Four Anjels Ltd had a new factory in Bishops Cleeve, Cheltenham. It had a 1295 square metre production floor as well as 180 square metres of canteen, offices, toilets, changing rooms and corridors.

Client Brief & Recommendation

The client was looking for a decorative finish that would give a uniform look to the canteen, offices, toilets, changing rooms and corridors. They also wanted a flooring that would be easy to keep clean.

Therefore, PSC recommended a Decorative flake system using a MT moisture tolerant epoxy resin base system with two coats of WD epoxy resin, in clear, silk to achieve the clients desired decorative finish.

In Preparation

We thoroughly cleaned and prepared the new concrete floor surface. We accomplished the edge work on the new concrete floor using a diamond grinding system. Following this, we vacuumed the area clean of all residues and dust.

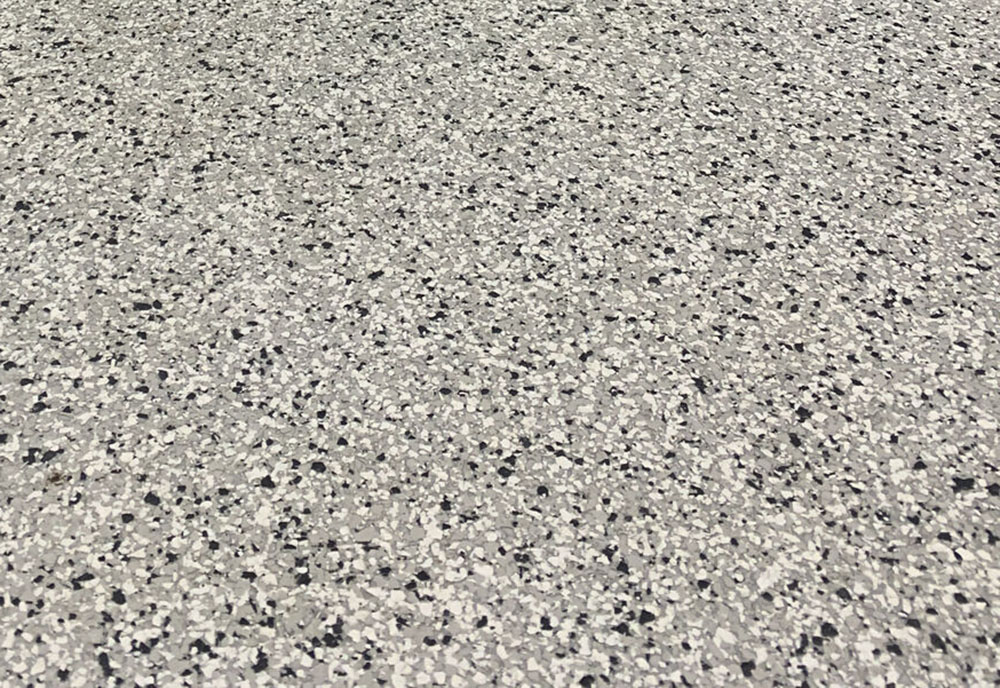

180 square metres Decorative epoxy resin flake system

We applied the Resdev Pumatect MT moisture-tolerant epoxy resin base system to the 180 square metre area. While the area was still wet, we fully covered it with the client’s chosen white, grey, and black decorative flake system.

Once dry the area was swept to remove any loose flakes and then de-nibbed using an STR machine with a fine pad. De-nibbing removes any protruding flakes leaving a flat surface. Two coats of Resdev Pumacoat WD epoxy resin, in clear, silk was laid to seal the decorative finish.

Mrs Julie Painting, Technical Director for Four Angels Ltd commented “We did not hesitate to call back PSC Flooring to look at our new premises in Bishops Cleeve, Cheltenham. The Decorative flake system they have installed in the canteen, offices, toilets, changing rooms and corridors looks great!”

Get in touch

For more information on Decorative flake systems, call us today on 01562 702047 and one of our team will be more than happy to help.

If you found this blog useful, you may wish to read about a previous one: How Does Silicone Affect Epoxy Resin?