Summary. Health and safety in a garage workshop are enhanced by PSC Flooring through the strategic use of demarcation safety lines on the floor. They recently upgraded Gammond Transport Ltd’s workshop by installing high build epoxy resin flooring with clear safety markings, complying with VOSA standards. This not only improved the workshop’s appearance but also ensured a safer working environment, completed within just four days, meeting both time and budget constraints.

As leading industrial flooring experts, we ensure that health and safety within working environments is a priority, especially in the case of garage workshops. This is through the use of demarcation safety lines on the floor.

Strict guidelines are in place for the safety inspection intervals for all commercial vehicles. A recommendation that inspections for compliance should fall between 4 – 13 weeks. The standard interval is generally 6 weeks. However, depending on the type of work you’re doing, the mileage covered and the terrain the vehicle is usually travelling on, this can differ.

According to the HSE (Health & Safety Executive) there have been over 7000 injuries and 33 deaths in the motor vehicle repair (MVR) industry over the last 5 years. HSE and Local Authorities (LAs) jointly enforce health and safety law in the motor vehicle repair (MVR) industry. In general terms, HSE enforce at body shops and mechanical repair/servicing premises, during vehicle recovery activities. As well as during any mobile MVR work e.g. at domestic premises or at the roadside. Most accidents in servicing/mechanical repair involve slips, trips and falls or poor manual handling.

Health and Safety in a Garage Workshop

To create a healthy working environment, experts recommend several building requirements:

- a clean workplace with a reasonable working temperature

- good ventilation

- suitable lighting

- the right amount of space and seating

- prevision of welfare facilities

- the right number of toilets and washbasins

- drinking water

- having somewhere to rest and eat meals

- a safe workplace with well-maintained equipment

- no obstructions in floors and traffic routes

- windows that can be easily opened and cleaned

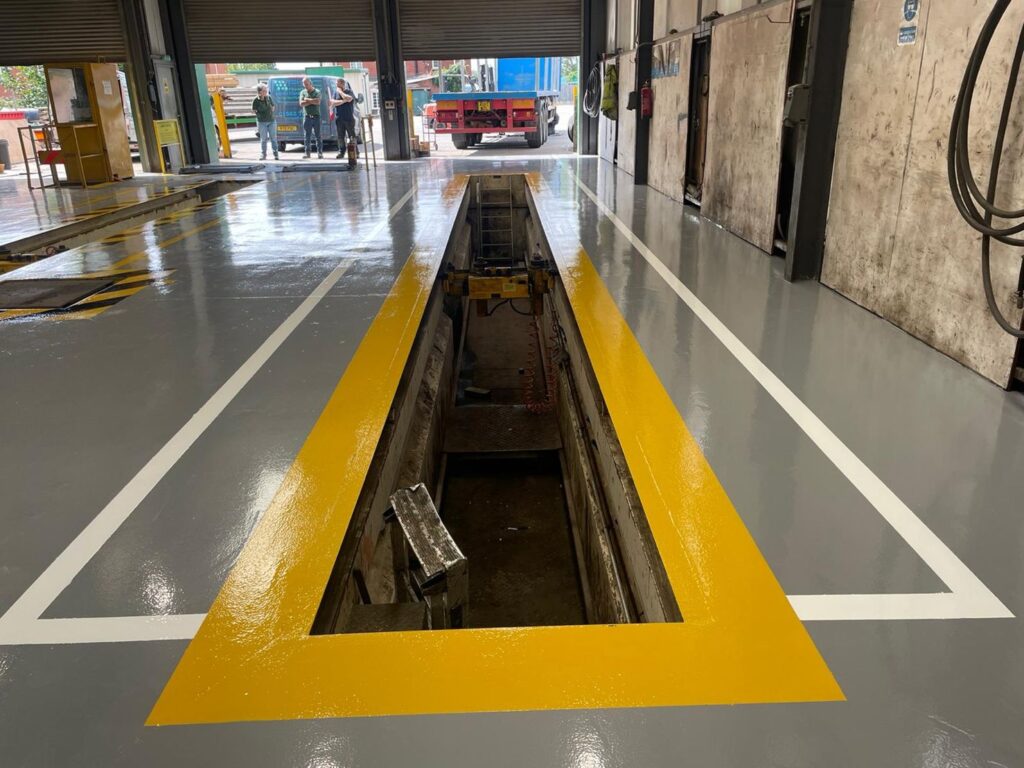

Recommendations often include heavy use of safety lining to adequately mark and signpost changes in height and floor levels. When dealing with any moving vehicles in a busy vehicle workshop demarcation lining is high on the agenda. Recently, Gammond Transport Ltd of Hereford called in PSC to refurbish the floor surface of their 280 square meter workshop area. Gammond Transport Ltd is a road haulage company which offers a range of services. They transport goods by road and as such have a fleet of HGV’s (Heavy Goods Vehicles) to service.

Client Brief and Recommendation

The client was keen to transform the space to make it brighter, lighter whilst still being hard wearing and easy to keep clean. Functionally they were looking to enhance the safety warning lines to adhere to strict health and safety guidelines. Upon inspection the 280 square metres was very worn/old concrete. The workshop also exhibited a buildup of mechanical grease and grime, and its yellow safety lining had worn away. It was recommended to install two coats of high build epoxy resin with demarcation lines.

Preparation of the Floor Surface for 280 Square Metres

In order to thoroughly clean and prepare the existing concrete surfaces Team PSC used the totally enclosed diamond grinding machine. The team combined this with a handheld 110v diamond grinder and then vacuumed clean all residues and dust. They repaired any localised damaged concrete and cracks as required using epoxy mortar compound and epoxy resin filler. Once prepared the entire floor surface was given two coats of Resdev Pumatect, high build epoxy resin flooring system, in the clients chosen light grey gloss.

Related: PSC Go Full Steam Ahead in the Transport Industry

Healthy and Safety Demarcation Lines on the Workshop Floor

The team added VOSA compliant safety lining using Pumatect V high build epoxy in safety yellow, black, and white, including:

- Masking out and applying a 400mm wide VOSA compliant safety lining band in yellow and black around the main pit and rolling road, and then adding a 100mm wide reversing line in safety yellow around it.

Adding Headlight Aim Tester Markings at intervals of 5m, 6m, 8m, 11m, and 13m in safety yellow. - The Service pit area received a 400mm wide band around the perimeter in safety yellow and 100mm wide reversing lines in white.

- 200mm wide VOSA compliant safety lining band was added to the top of the pit steps area in safety yellow and black.

Overall to complete the job it took just 4 days and was completed on time and in budget.

“PSC have completely transformed our HGV workshop. We are extremely pleased with how the job has turned out and are grateful for all the hard work put in by the team!”

Mrs Melissa Prosser of Gammond Transport Ltd

If you have found this blog useful, take a look a previous one: Garage Workshop Flooring Solutions at PSC Flooring