Beakbane – Engineering & Manufacturing Flooring

PSC were invited to refurbish a 400 square metre area for local engineering company Beakbane. Kidderminster based Beakbane Ltd are leading steel fabrication manufacturers and distributors of machinery protection systems.

Client Brief and Recommendations

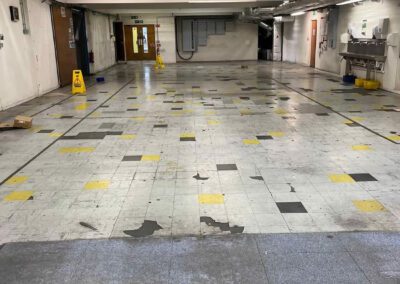

The client was looking for a hardwearing floor to replace the vinyl tiles in their Tea Trolley Assembly Area. PSC recommended a 4mm MD heavy duty polyurethane screed. Moreover, at the site visit it was noted that the entire floor was covered in 2mm thick, 300mm x 300mm vinyl tiles, which would to be removed. Also, underneath the tiles was thick black adhesive that would require a heavy shotblast to remove.

In Preparation

We uplifted the existing vinyl tiles using the diesel-powered terminator tile lifter and gave the entire area a heavy shotblast with the captive shotblasting machine to remove the tile adhesive and prepare the floor. Once exposed, we found the concrete was very rough and required extensive repairs and an epoxy resin scratch coat. After the repairs, we primed the floor with an epoxy resin priming system, incorporating a heavy scatter of 0.7 to 1.2mm quartz aggregate.

After that, 6mm x 6mm saw cuts were then made around drains, door entrances and where necessary to toe in and anchor screed.

400 sq mtrs of 4mm Resdev Pumadur MD polyurethane screed

A nominal 4mm heavy duty Resdev MD polyurethane screed in the clients chosen smooth, matt, grey colour was then hand trowelled onto the floor.

Then, once dry 6mm x 6mm expansion joints were saw cut, knocked out and reintroduce expansion joint with polyurethane jointing compound, to 52 linear metres.

Completed in just 6 days of hard work the project has turned out amazing and ready for the new machines to be delivered – Another great job for the team at PSC Flooring.