Expert Tooling – Leyland – Engineering and Manufacturing Flooring

Expert Tooling, a long-standing customer of PSC Flooring asked to look at a new production line at major HGV manufacturer in the northwest of England. As leading manufacturers of industrial automation systems, assembly tooling, automated assembly, special purpose machinery and single and multi-robotic cells, including robotic assembly, Expert Tooling recognise that the flooring within these areas plays a vital part.

Client Brief and Recommendation

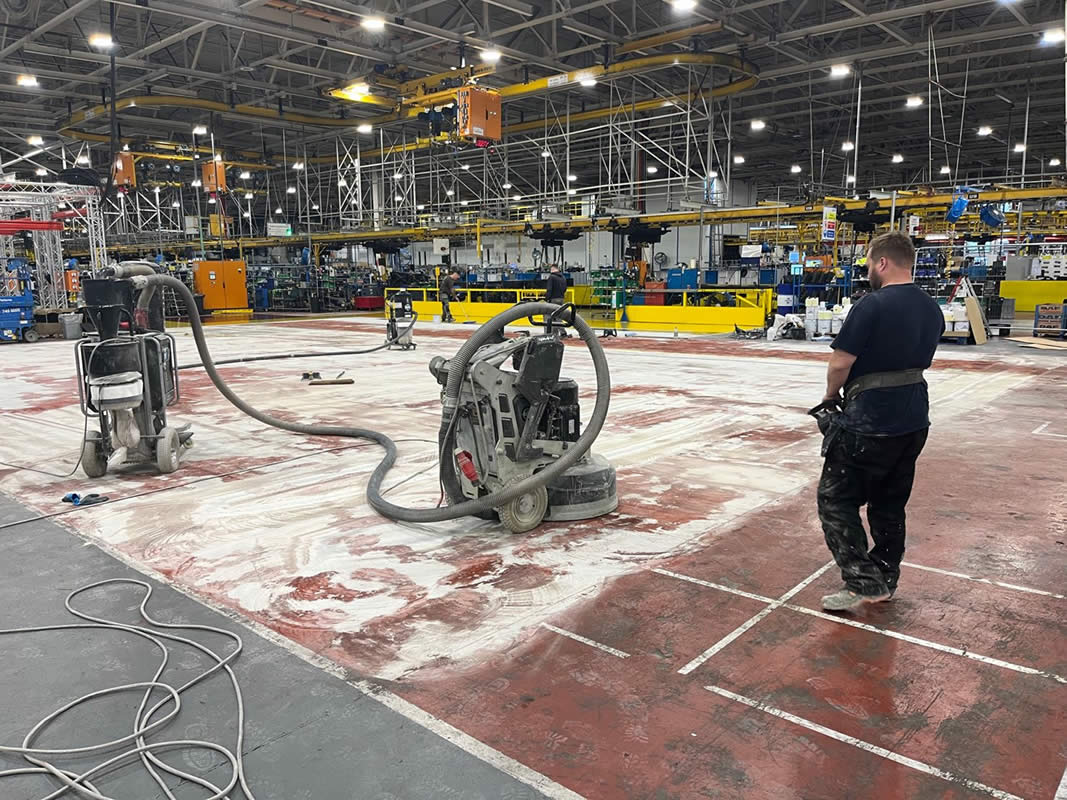

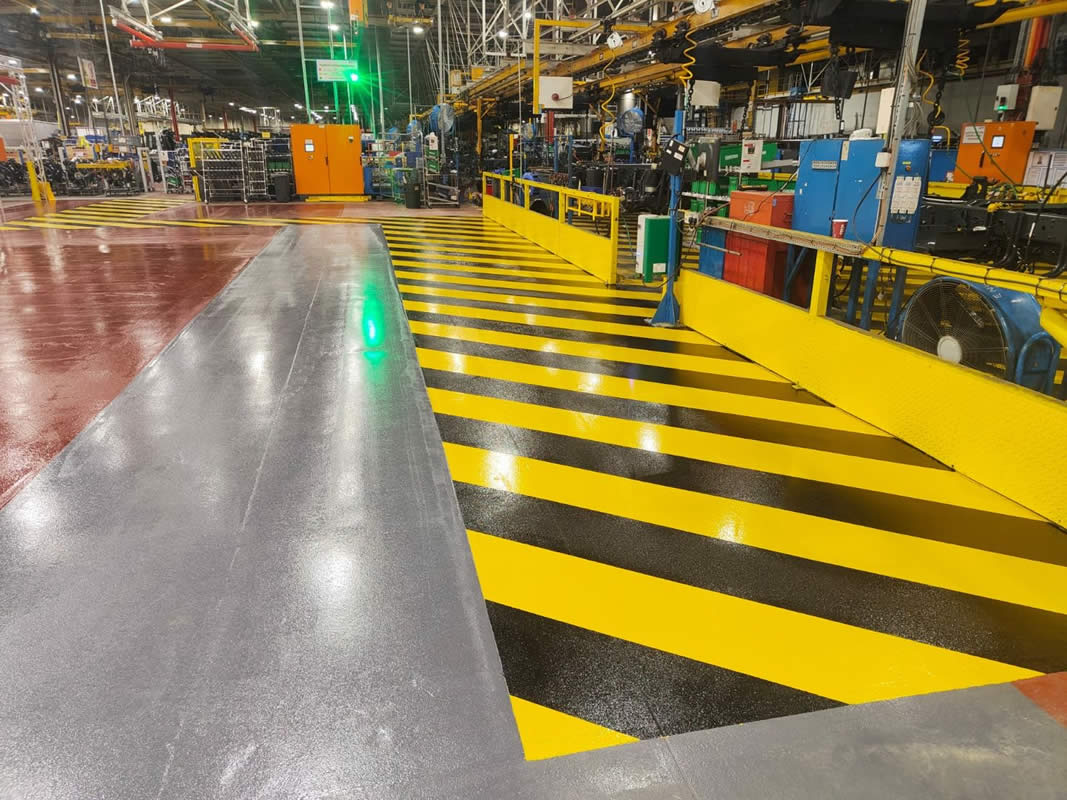

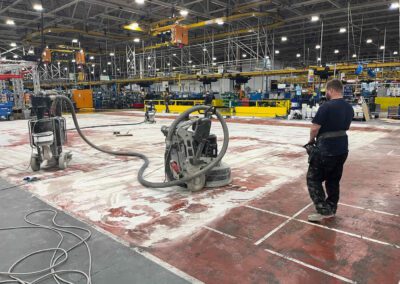

At the site visit it was noted that the 650 square metre area had layers of failed floor paint and would require grinding back to ensure good adhesion for the new coating system. Expert Tooling specifically wanted to demark the trucking gangway with safety yellow and black hatching to denote crane area.

In preparation

In order to remove the multiple layers of failed floor coatings, and thoroughly clean and prepare concrete floor surface a captive double headed diamond grinding machine was used for the bulk area and the edgework by diamond grinding with a totally enclosed handheld 110v diamond grinder. Once ground back the entire area was vacuumed clean of all residues and dust and repairs were made to any localised damaged concrete, holes, bolt holes as required using resin filler.

650 sq mtrs of two coats of KDR Epocoat high build epoxy resin coating system

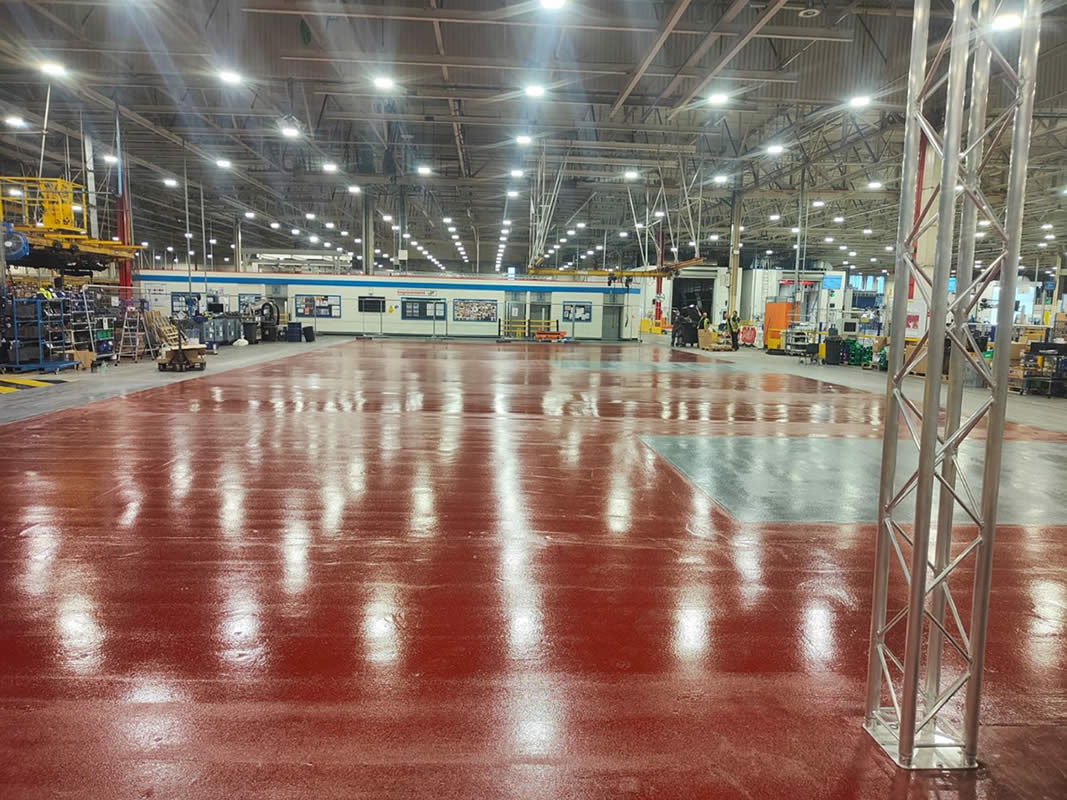

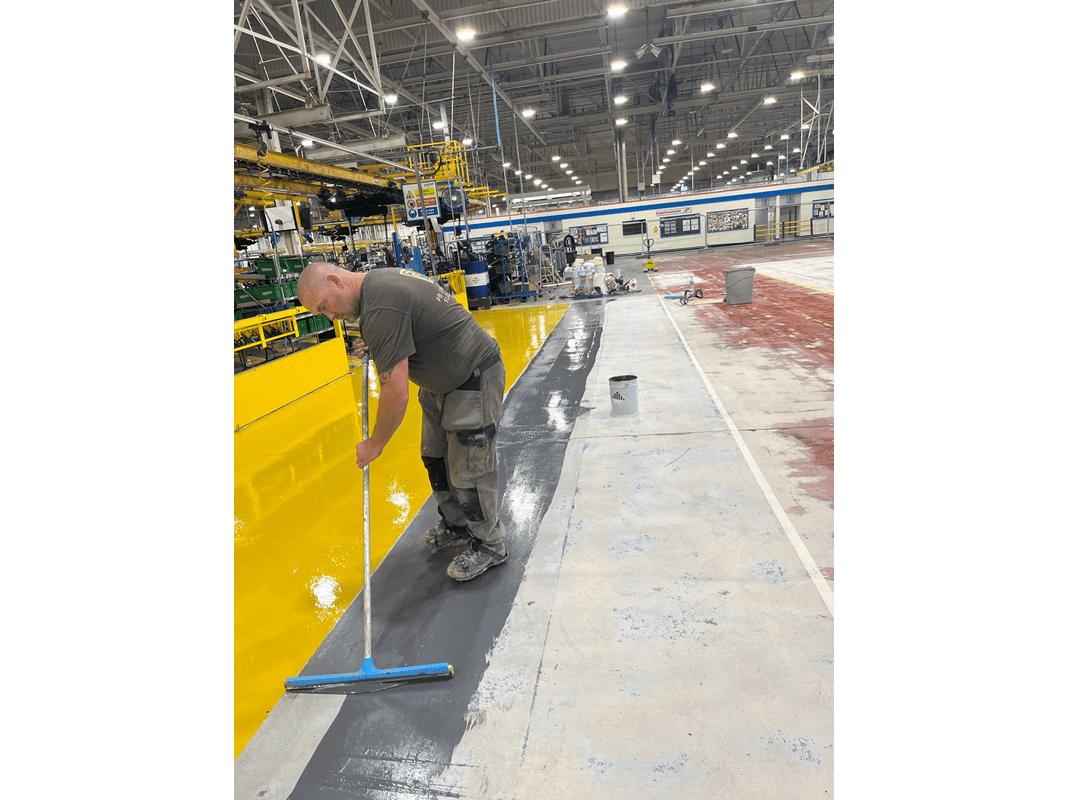

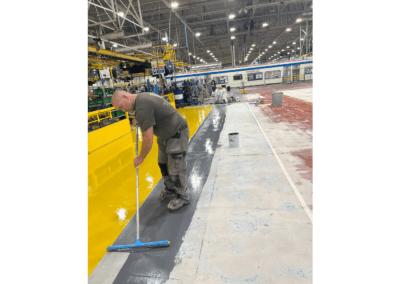

Once fully prepared, we marked out the 650 square meter area into sections. The main areas received two coats of KDR Epocoat high build epoxy resin coating. We added 0.3 – 0.6mm anti-slip aggregate to enhance safety. The red was applied to the production area, and mid grey to the trucking gangway. Safety yellow and black hatching marked the crane area.

The entire flooring refurbishment project was completed in Expert Tooling Leyland’s shutdown week, ready for new automation line to be installed.