Prestige All Parts Ltd – Vehicle Workshop Flooring

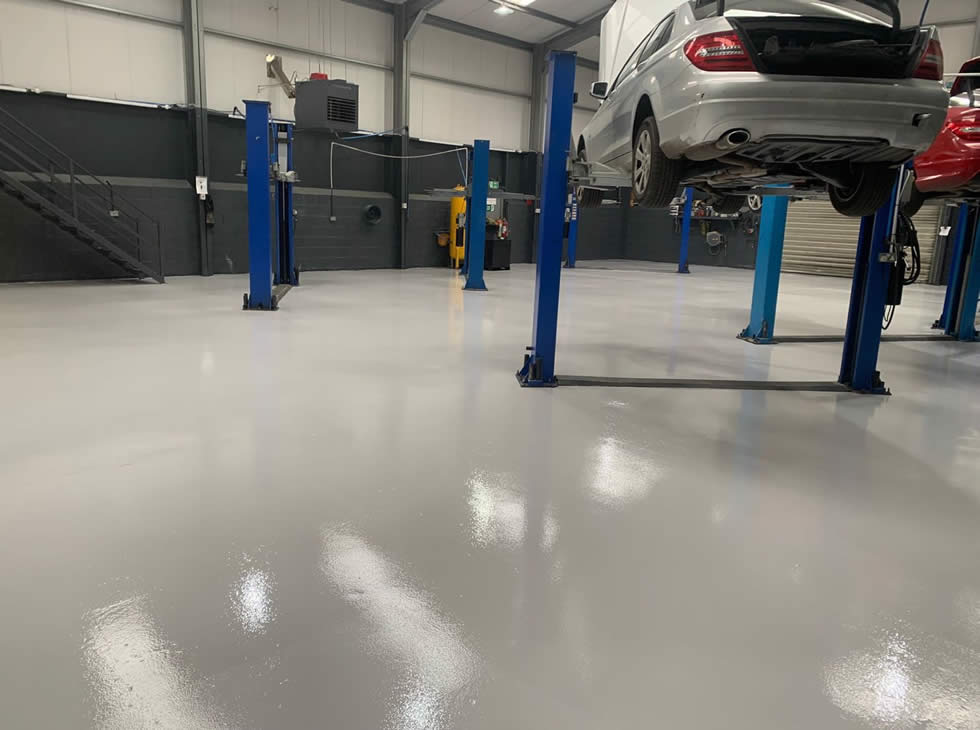

PSC Flooring, a leading name in industrial flooring contractors, was invited by Prestige Allparts Ltd, a renowned Mercedes repair center in Oldham, to assess their 350 square meter vehicle workshop. Specialising in high-end Mercedes repairs, Prestige Allparts sought a premium finish aligned with the durability and aesthetics of a high build epoxy resin flooring system.

Client Brief & Recommendation

During the site visit, the client outlined their need for a hard-wearing, easy-to-clean resin flooring solution. Having relied on traditional floor paint for many years, they now required a high-gloss, resilient surface to meet the demands of a busy workshop.

It became clear that the existing floor, with multiple layers of failed paint, required extensive preparation before any new flooring could be applied. As experienced epoxy flooring contractors, PSC recommended a two-coat High Build Epoxy Resin flooring system. This solution was designed to provide a durable, low-maintenance finish. It ensures the industrial resin flooring can withstand daily vehicle traffic. At the same time, it maintains a professional appearance.

Preparation of floor surface

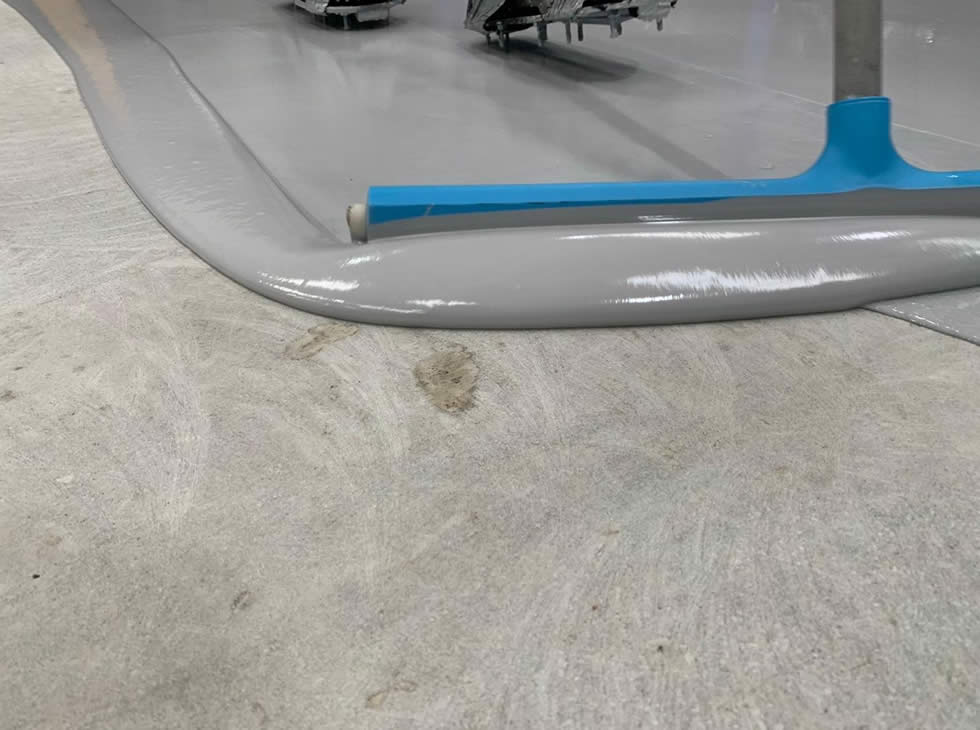

To ensure optimal adhesion for the High Build Epoxy Resin flooring system, PSC Flooring undertook a comprehensive floor preparation process to address layers of failed floor paint and prepare the concrete substrate.

For the main area, we used a triple-headed diamond grinding machine. This provided a completely enclosed system to minimise dust. It ensured a smooth and clean surface. For the edges, we used a fully enclosed 110v hand held diamond grinder. This process ensured precision and uniformity throughout all areas.

Once the grinding phase was complete, the floor was thoroughly vacuumed to eliminate all residues and dust, creating a flawless base for the new flooring. As experienced resin flooring contractors, PSC repaired localised damage, including cracks, holes, and areas of deteriorated concrete, using epoxy resin screed and polyurethane mortar.

Epoxy resin coating system totalling 375 square metres

The entire floor was then given two coats of KDR Epocoat high build epoxy resin flooring system, in the clients chosen light grey, gloss.

The work was completed in just 2 days leaving the floor fresh and ready for the team at Prestige Allparts Ltd.